Factory EL Image Processing: The First Line of Defense Against Defective Panels

In the fast-paced world of solar energy, panel quality not only guarantees investment returns but also places the credibility of brands, contractors, and consultants under scrutiny. One of the hidden yet costly challenges in solar projects is the delivery of defective panels from the factory—panels that appear intact but conceal micro-cracks, cell fractures, or connection issues. These defects can only be identified through Electroluminescence (EL) testing.

At Aseman-Rasad Hadi, leveraging extensive field experience and advanced image-processing algorithms, we provide a vital service: specialized analysis of EL images before shipment from the factory. This service acts as an intelligent filter, preventing defective panels from reaching the site and reducing hidden future costs.

________________________________________

Why EL Testing Before Shipment Matters

In many projects, EL testing is performed only during commissioning or after installation. At that stage, replacing or returning defective panels requires significant time, cost, and effort—often nearly impossible under current sanctions. In contrast, analyzing EL images at the factory, before shipment, offers a golden opportunity to identify and eliminate defective panels at the source.

Key benefits include:

- Preventing delivery of panels with invisible cracks, cell fractures, or internal connection issues

- Reducing the risk of future power loss in the plant

- Documenting panel quality to defend against future claims, contractual disputes, or insurance issues

- Increasing employer and investor confidence in the quality control process

________________________________________

How the Service Works

Factories typically capture EL images of panels at the end of the production line. While valuable, these images remain raw archives without specialized analysis. We process these images using proprietary algorithms and deliver a detailed report on each panel’s condition.

Process overview:

- Receiving EL images of panels from the factory (standard format) before shipment

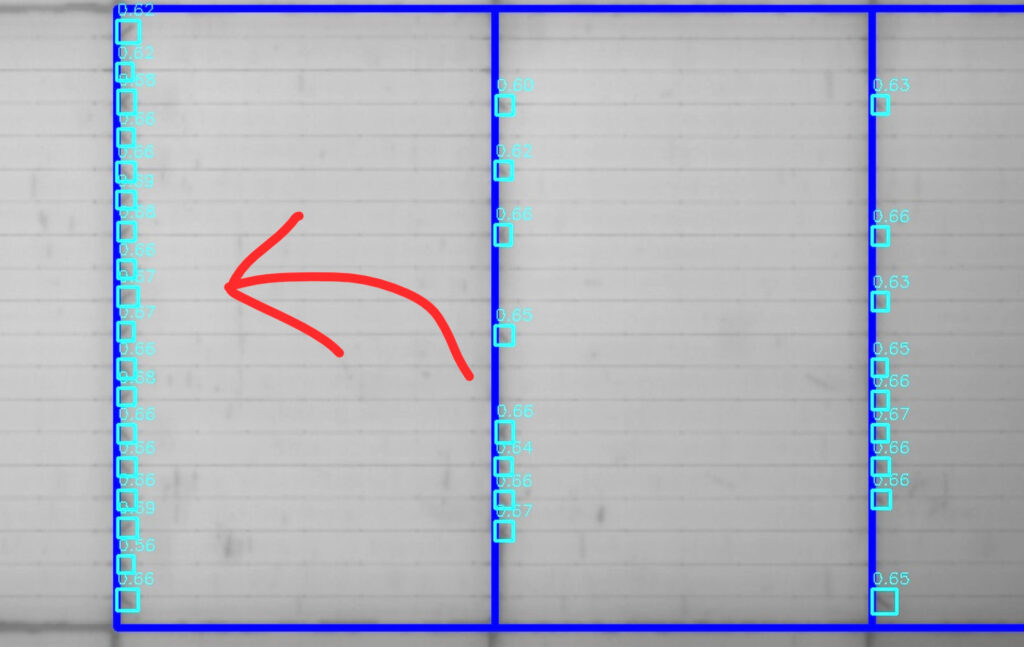

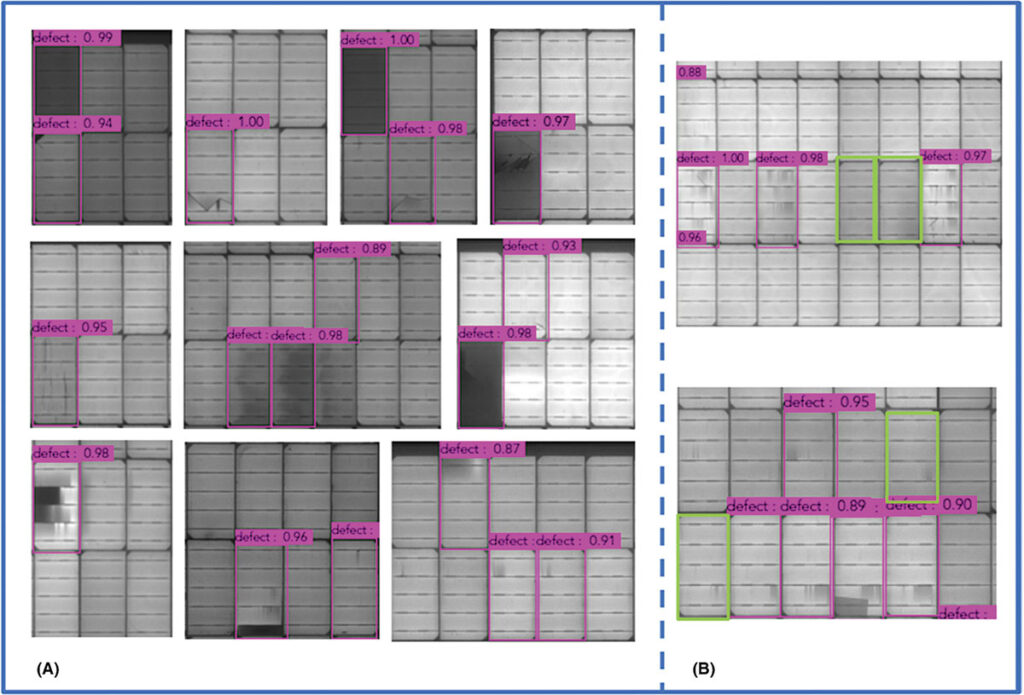

- Automated image processing using AI algorithms to detect cracks, fractures, dark spots, and connection anomalies

- Categorizing panel defects

- Delivering a final report with visual documentation and recommendations for removal or replacement of defective panels, including their serial numbers

________________________________________

Types of Defects Identified

Our algorithms can detect a wide range of defects, including:

- Micro-cracks invisible to the naked eye and undetectable even in factory Flash Tests or IV-Curve tests, yet critical for long-term performance. Types include:

- V Type

- T Type

- Cross

- Line

- Branch

- Broken Fingers

- Dark spots caused by weak soldering or dead cells

- Mechanical stress anomalies arising during the manufacturing process

________________________________________

Our Experience, Your Trust

This service is built upon years of expertise in field testing, thermography, IV-Curve analysis, and EL diagnostics at solar sites. We have now shifted this expertise to a preventive stage: identifying defective panels before they ever reach the site.

In recent projects, by analyzing hundreds of thousands of factory EL images, we successfully identified defective or suspicious panels prior to shipment—saving costs, time, and reputation.

________________________________________

Conclusion: Prevention Is Better Than Cure

In solar energy, every defective panel represents a weak link in the energy production chain. By leveraging EL image processing before shipment, these weaknesses can be identified and eliminated before they escalate into crises.

At Aseman-Rasad Hadi, we are ready to deliver this service with precision, speed, and full transparency—ensuring your solar projects are built on a solid and reliable foundation from the very beginning.