Electroluminescence (EL) Testing: The Most Accurate Diagnostic Tool for Solar Panels

In the solar energy industry, what appears intact on the surface may conceal hidden defects that, in the near future, lead to performance loss, reduced generation, and irreparable financial damage. Electroluminescence (EL) testing is the most precise method for identifying these hidden defects in solar panels—a specialized service provided by Aseman-Rasad Hadi with portable equipment and an experienced technical team, offered in two execution formats.

Why EL Testing Matters

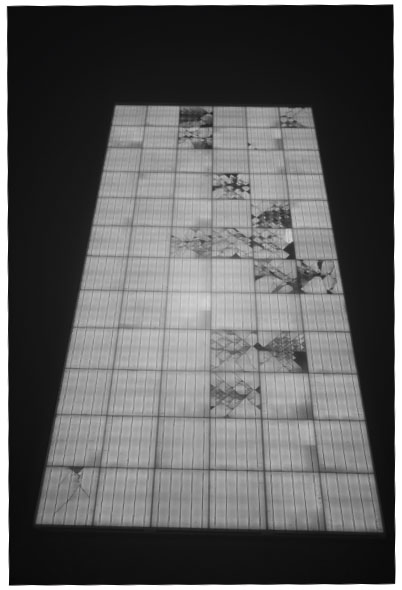

EL testing applies electrical current to the panel and records infrared images of cell emissions, revealing the internal structure of the panel. Unlike performance or thermal tests that only show overall output, EL testing can detect a wide range of structural defects at early stages, including:

- Micro-cracks in cells

- Fractures caused by transportation or installation

- Manufacturing defects

- Dark spots from poor connections or cell degradation

These defects may not initially affect output power, but over time—under electrical load, thermal cycling, and mechanical stress—they expand and cause significant power loss. By then, the project is completed, EPC warranties are released, and the plant owner faces serious issues without legal protection.

Two EL Testing Methods by Aseman-Rasad Hadi

We provide EL testing in two formats tailored to project stage and client needs:

1. Portable EL Testing at Panel Delivery (Pre-Installation)

Our technical team, equipped with portable devices, performs statistical sampling based on ISO 2859 at customs or project sites before installation. EL testing is conducted on samples, and results are classified as:

- Healthy panels

- Minor defects (acceptable, low risk)

- Major defects (moderate performance risk)

- Critical defects (unacceptable, high risk)

⚠️ Even a single critical defect can invalidate an entire large-scale shipment.

This method enables buyers and contractors to:

- Prevent delivery of defective panels

- Obtain technical documentation for warranty claims

- Avoid installing damaged panels and future issues

2. Field EL Testing at the Power Plant (Post-Installation)

This method complements aerial thermography. Using drones, we first identify suspicious panels or hot spots across the plant. Then, our team performs targeted EL testing on those defective panels.

This two-step approach—thermography for initial screening and EL for precise diagnostics—ensures:

- Faster, more targeted, and cost-effective inspections

- Avoidance of expensive full-scale testing

- Detailed visual documentation of defective cell structures

- Accurate technical decisions for replacement, repair, or warranty claims

If needed, IV-Curve testing is also performed as a complement to assess electrical performance.

EL Testing at Multiple Control Points: Identifying the Source of Damage

A key advantage of EL testing is its flexibility across project checkpoints—from factory to installation site. This helps pinpoint the exact origin of damage:

- Factory EL Testing: Reveals manufacturing defects

- Pre-Installation EL Testing: Detects transport, storage, or environmental damage

- Post-Installation EL Testing: Evaluates installation quality by contractors

This multi-stage approach simplifies liability identification and enables legal, warranty, or insurance follow-up.

Our Experience in Large-Scale Projects

Aseman-Rasad Hadi proudly delivers this specialized service in major projects such as:

- 600 MW Mobarakeh Steel Solar Plant

- 100 MW Chadormalu Solar Plant

- 40 MW Golgohar Sirjan Solar Plant

- 12 MW Momtazan Cement Solar Plant

- 10 MW Farab Solar Plant

- 10 MW Anarak Solar Plant

- And several other industrial-scale projects

This proven track record makes us a trusted reference in EL testing nationwide.

EL Testing: A Key Tool in Insurance Assessments

In insurance evaluations of solar panels, EL testing is recognized as the most accurate and reliable diagnostic tool. EL images provide undeniable evidence of panel structural conditions and play a decisive role in claims, warranties, and legal disputes. We have repeatedly collaborated with insurance companies to determine damage origins and verify panel quality.

Why Aseman-Rasad Hadi?

- EL testing performed under ISO 2859 standards

- Portable equipment and specialized team for on-site testing

- Proven success in large-scale projects

- Precise documentation for technical, legal, and insurance decisions

- Combination of EL with thermography and IV-Curve for comprehensive diagnostics

- Capability to perform testing at multiple checkpoints to identify damage sources

For expert consultation, service booking, or project references, contact us. We are here to safeguard your solar investment with precision, expertise, and advanced tools.