rone-Based Inspection of Refinery Flares: Precision, Safety, and Efficiency

In the oil, gas, and petrochemical industries, one of the key applications of drones is the inspection of refinery flares. Flares are critical components of such complexes, and their shutdown is equivalent to a plant shutdown.

Limitations of Conventional Flare Inspection by Human Workforce

Requirement for special cranes with tall booms due to flare heights averaging 80 meters, leading to high costs and long inspection times

- Long intervals between inspections due to logistical challenges, increasing the risk of undetected issues

- Plant shutdowns required to turn off the flare for inspection, causing production losses

- Inability to observe flare performance during operation and detect related issues

- Lack of systematic documentation of inspection observations

- Limited ability to inspect flares from all angles

- High safety risks for inspection personnel

Advantages of Flare Inspection Using Drones

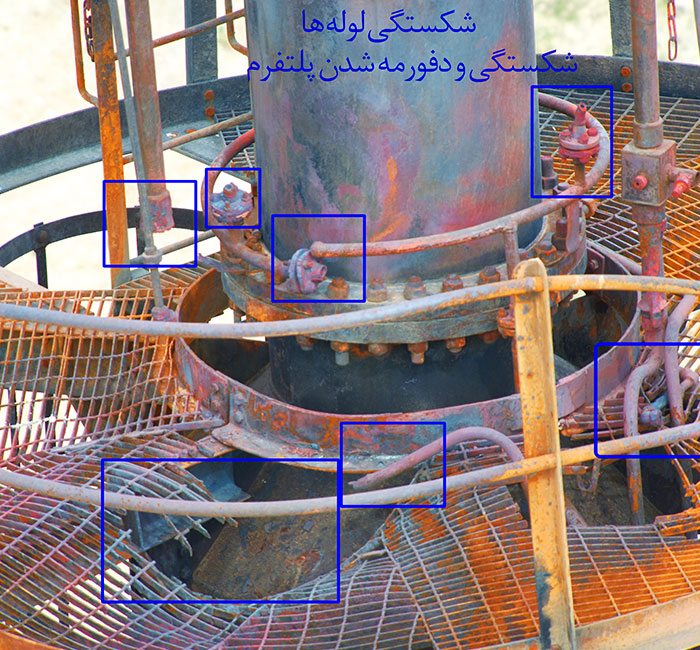

Comprehensive documentation of inspection results with photos and videos tagged with geographic and time data, enabling expert collaboration, data sharing, and trend analysis of observed issues

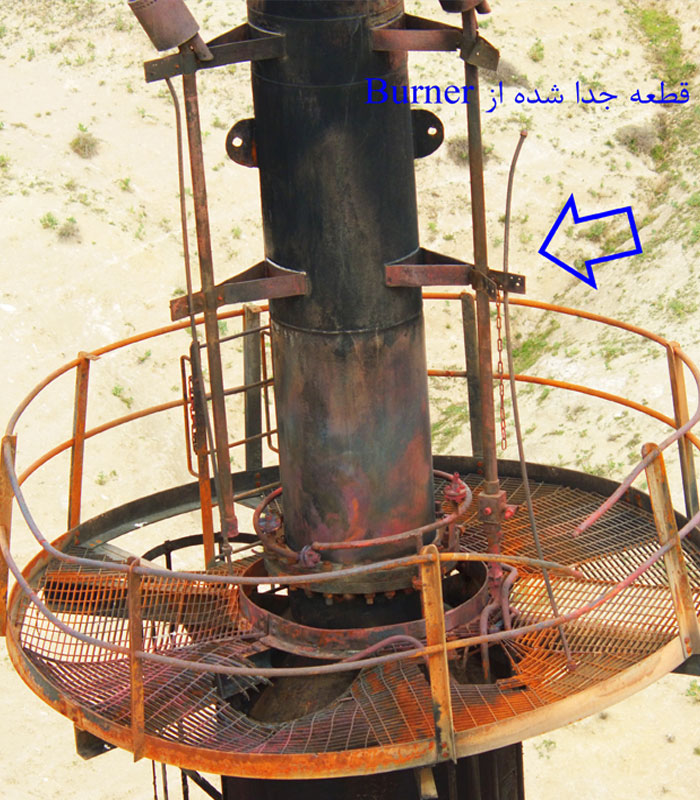

- Use of photogrammetry and 3D modeling of flares, allowing dimensional measurements on generated models

- Integration of thermal cameras on drones to record temperature data of flare components during operation

- Ability to conduct inspections at shorter intervals and detect defects more quickly

- High-resolution recording of flare performance in both photo and video formats

- Full-angle inspection of flares and flare tips

- No need for plant or flare shutdown

- Elimination of safety risks for personnel

- No requirement for cranes

Global Adoption of Drone-Based Flare Inspection

Leading oil companies such as Total, Shell, and BP are already utilizing this technology. Aseman-Rasad Hadi, in line with global advancements, provides aerial flare inspection services for refineries.

Our Experience in Iran

We have successfully conducted aerial inspections of:

- The flare at Iran Chemical Industries Complex (LAB)

- The flare of Gachsaran Oil & Gas Exploitation Company (a subsidiary of National Iranian South Oilfields Company)

Both projects were completed with full client satisfaction.