IV-Curve Testing Services by Aseman-Rasad Hadi

Understanding IV-Curve Testing in Solar Power Plants: Electrical Performance Analysis of Solar Panels

🔍 Introduction

The IV-Curve (Current-Voltage Curve) test is one of the key tools for evaluating the performance of solar panels. It enables precise assessment of the electrical behavior of panels under real conditions and serves as a complementary test to aerial thermography and EL testing. It plays a vital role in detecting defects, identifying efficiency losses, and optimizing system performance.

⚙ What Is the IV Curve?

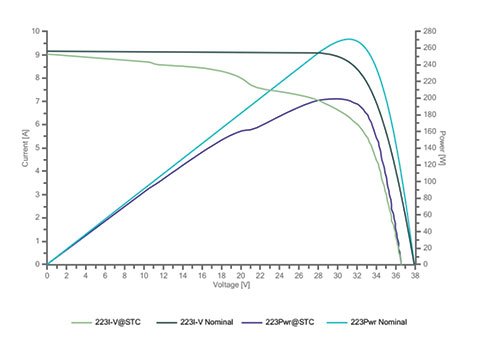

The IV curve illustrates the relationship between the output current (I) and the generated voltage (V) of a solar panel under varying irradiance conditions. Key points include:

- Voc (Open-Circuit Voltage): Maximum voltage when current is zero

- Isc (Short-Circuit Current): Maximum current when voltage is zero

- MPP (Maximum Power Point): The point where the product of current and voltage reaches its maximum

🧪 How Is the IV-Curve Test Performed?

To plot the IV curve, the testing device is connected to the panel or string. Simultaneously, panel temperature and irradiance are measured and recorded. Current and voltage are then captured at different operating points. After applying correction factors, the measured values are referenced to STC (Standard Test Conditions).

- Portable IV-Curve testing device with panel temperature and irradiance sensors

🛠 Applications of IV-Curve Testing

- Detecting panel defects and efficiency losses

- Comparing with factory reference curves to identify performance deviations

- Periodic monitoring of solar plants for preventive maintenance and extended system life

- Evaluating installation quality to verify proper connections and minimize losses from incorrect installation

📈 Analysis of Test Results

The obtained curve is compared with the reference curve. Deviations from the standard shape may indicate:

- Voltage or current reduction due to shading or surface contamination

- Power loss caused by high temperature or poor connections

- Presence of defective cells or weak soldering

- And more

📌 Key Execution Notes

- Testing must be performed under stable irradiance; irradiance levels are recorded during the test.

- Panel temperature is measured and recorded for each test using a contact sensor.

- Recommended during panel delivery and periodically (e.g., every 6 months).

- High-efficiency panels (>19%) require specialized equipment, as their high inrush current during testing can damage standard devices.

Electrical Parameters Measured by IV-Curve Testing

- Maximum Power

- Open-Circuit Voltage

- Short-Circuit Current

- Fill Factor

- And more